How many parts are in a car engine? That is one of the most frequently asked questions by an average car owner who is not well familiar with cars. The answer to this question may surprise you. Most of the cars we know have at least one engine, but that does not mean that it is the entire car. There is actually only one cylinder in the engine of a car. However, the car engines have different numbers depending on the model and the make of the car.

In general, the more car engines there are, the higher the car’s speed. It is for this reason that the speedometer must also be able to read the engine’s RPM. RPM is the unit of time needed for the engine to start. Thus, if one has an extremely fast car, its RPM would be faster than the average vehicle, because its engine is running at top speed when it is started. Thus, the question ‘how many parts are in a car engine?’

Of course, it is impossible to give an exact answer to the question ‘How many parts are in a car engine?’. However, it is still possible to give a rough estimate based on the size, type of the car engine, its intended use and its price. Thus, before buying a car, always ask around, read the manual or inquire from the seller regarding its engine size and the approximate number of cylinders. By doing so, you will have enough information to make a good decision about your next car.

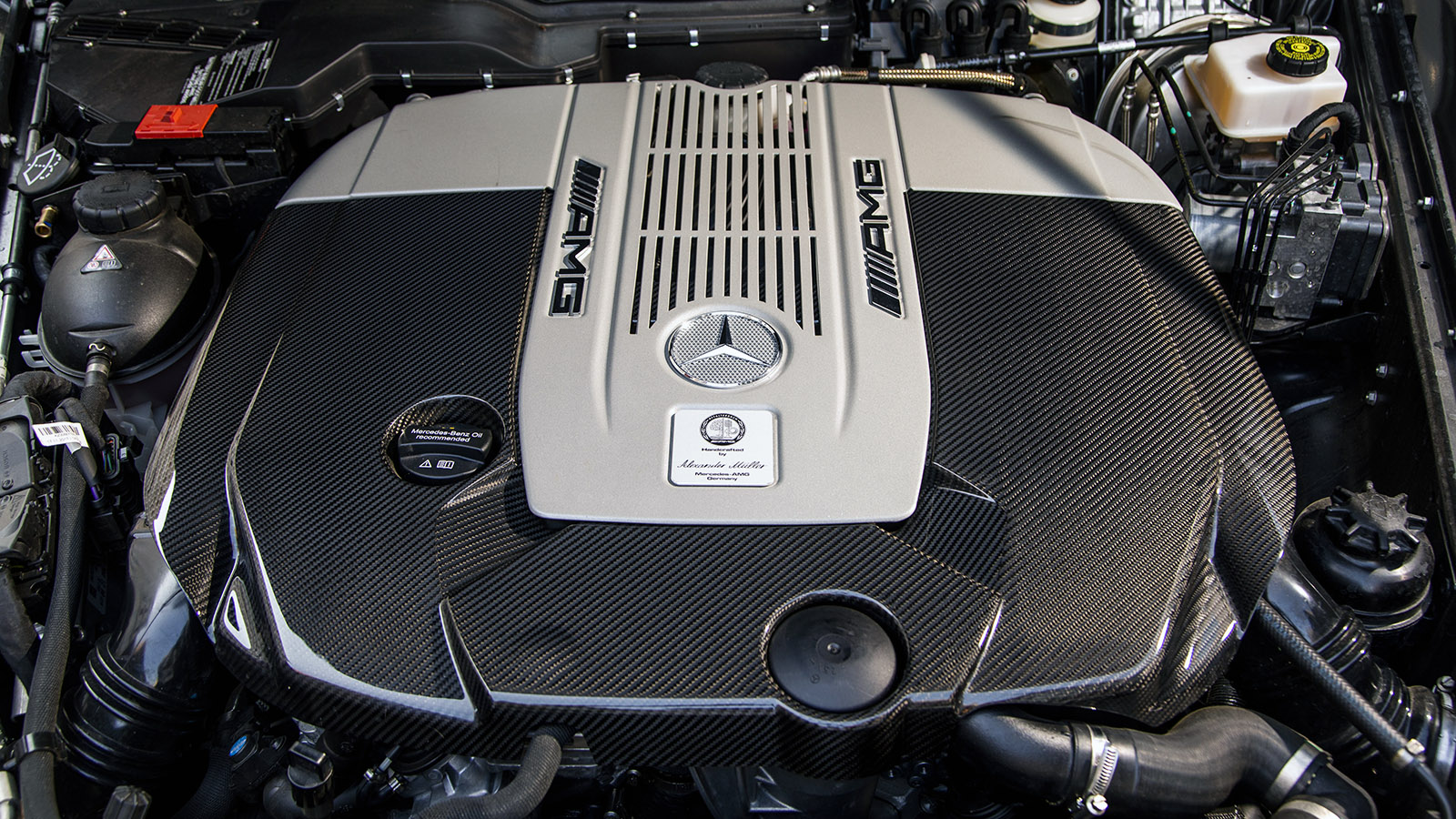

How does a v6 engine work?

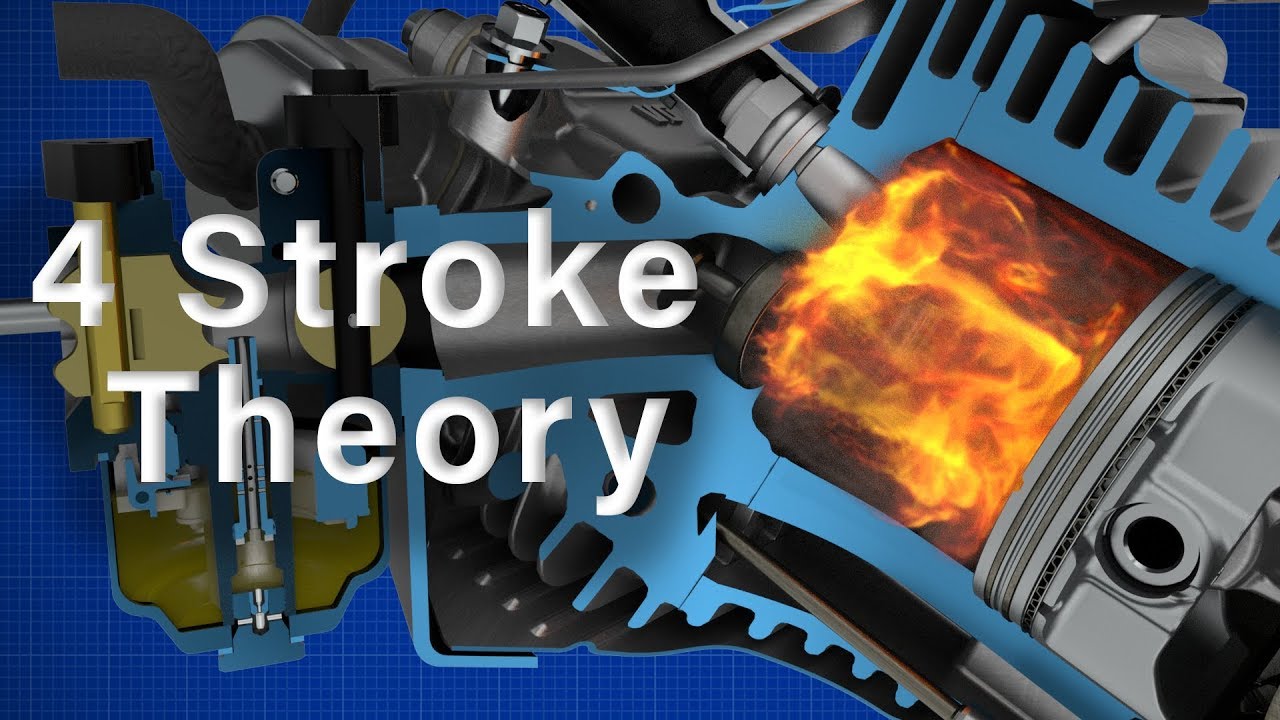

How does a V6 engine work? The engine is basically made up of four main components. The intake system, the engine exhaust system, the transmission and the final drive. All these parts work together to provide power for your vehicle. The intake system of a V6 engine takes air in through the carburetor, then it passes through an intake manifold which then directs the air to the engine’s intake manifold, where it is compressed and cooled before it enters the engine. As the engine runs, the air is compressed and as the engine reaches its cruising speed, the air is released from the exhaust system through the exhaust pipes.

The engine’s intake port is directly connected to the engine’s intake valve, which lets in clean air and the compressed air is directed to the engine’s exhaust port. The exhaust port on the other hand receives the compressed air and uses it to cool off the components of the engine. The result of this is the exhaust gas having less pressure than that of the compressed air, which results in the reduction of the power of the engine.

While the engine is working, another function that it performs is that of the generator. The generator uses the engine’s exhaust port and gasoline, which give it an energy charge to use as energy when it is needed. In short, the engine performs all the functions necessary to power up your car so you can get to where you have to go without any problems at all. When you are looking to purchase a car and you ask the sales person or the guy sitting in front of you how does a V6 engine work, you should know by now that it uses four major and minor components, which are the carburetor, the engine’s intake, the exhaust, the final drive and the generator.

What causes low compression?

What causes low compression? This is an inevitable question that boat owners ask all the time, as they try to figure out how much of their engine room to designate for dry dock storage, or whether they should just install an oil tank. Low compression, also known as damping, happens when the air flowing through a particular pipe gets below the level of the port (the lowest point where the boat can be drained into the water), or above the port (the highest point where the boat can be drained overboard). This air-level issue is an effect of a number of factors, including the rate of port flow, the type of outboard engine that’s causing the problem, and the ambient temperature and pressure of the area in which the boat is docked. The cause of the problem may be something as simple as a lack of oil pressure, or it may involve something as complex as a leak in the inboard oil system.

The most common engines in boats (the two-stroke and four-stroke types) generate air by compressing and then blowing it through a specially designed nozzle. The two-stroke generally uses oil pressure to lubricate and cool the engine and is one of the most popular types of boats in the world. However, because the inboard motor creates a suction that is similar to that produced by the water pump on a car, it can create a negative pressure condition in certain places around the boat’s superstructure. As the pressure continues to build, the boat begins to act “wet.” A boat with a high port side pressure (high oil pressure) will act wet, regardless of whether it’s being used dry or in saltwater; the same goes for a high transom pressure side (high oil pressure inboard) as well.

A major contributor to low compression is damage to the outboard motor, which is usually located in the center of the boat. Often the damage is a result of a leaky fuel line, but sometimes the entire engine can be damaged by cracks caused by a disintegrating head gasket. If the boat has an automatic outboard motor with a leaky fuel line, the problem may lie with the fuel line or between the fuel tank and the head gasket, which is often an inexpensive repair. In either case, the affected head gasket should be replaced immediately, and the boat should be taken in for repair.